FLUX liefert den Überblick über die Produktion für KMU

– ohne Systemumstellung

Flux – Das einfache MES für den Mittelstand!

Mit FLUX erweitern Sie Ihre bestehende Systemlandschaft, Ihr bestehendes ERP-System, um relevante Kennzahlen und Visualisierungen aus der Produktion. Sie erhalten Transparenz in Echtzeit zur Steuerung und Optimierung Ihrer Fertigung.

Willkommen in der Zukunft. Willkommen bei FLUX.

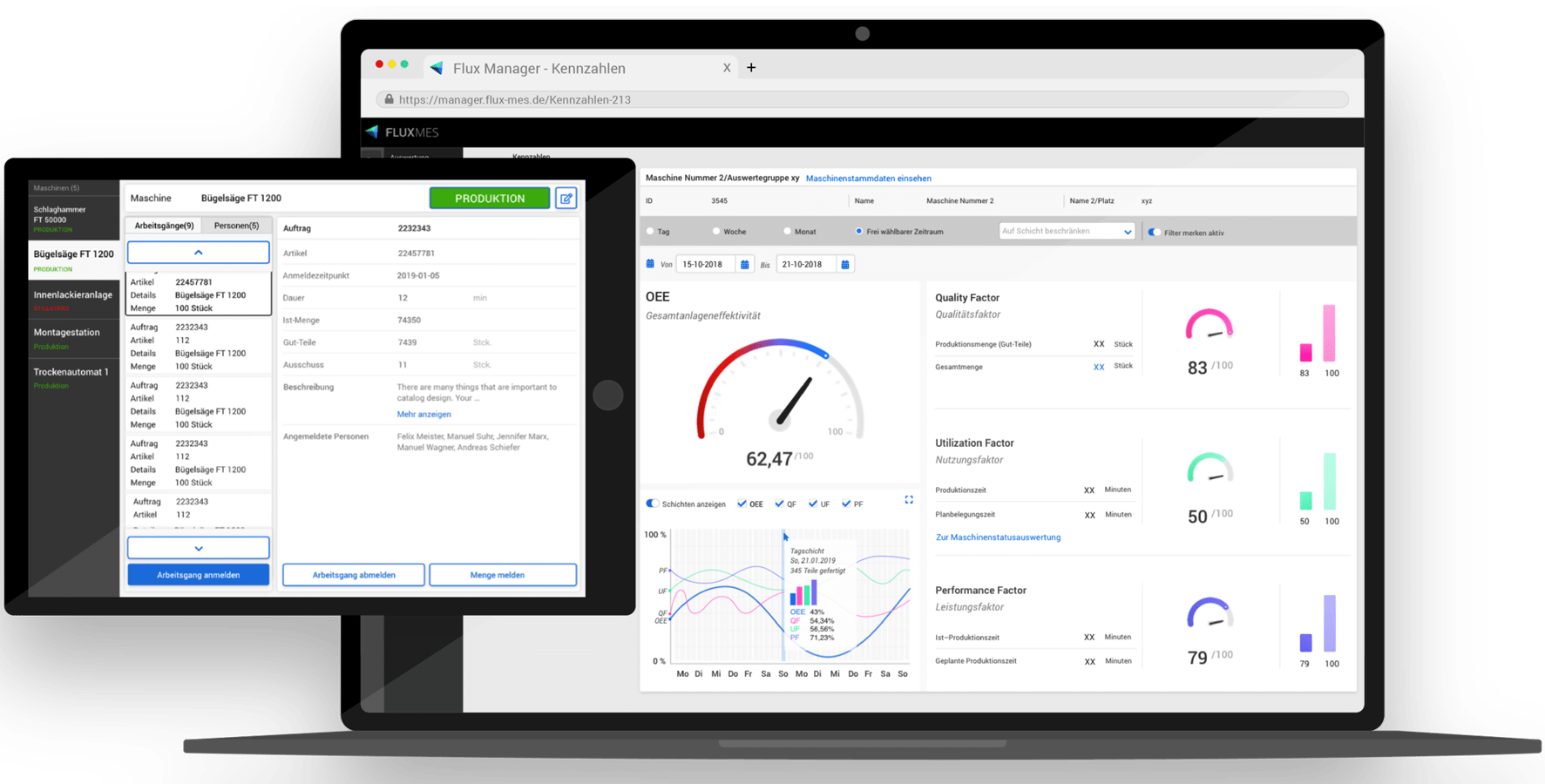

Das Flux Produktions Dashboard

OEE. Natürlich in Echtzeit. Und auf dem Smartphone.

Mit FLUX sehen Sie in Echtzeit, was gerade in der Produktion passiert. FLUX misst dabei Gesamtanlageneffektivität (OEE), zeigt Maschinenauslastungen und alarmiert bei Ausfällen – in Kennzahlen sowie ansprechend visualisiert und für die jeweilige Betrachtungsebene zusammengefasst. Egal wo Sie sich gerade befinden. Auf PC, Tablet und Smartphone.

Add-ons zur Erweiterung und Skalierung von FLUX

FLUX passt zu Ihren Bedürfnissen und bietet eine Vielzahl an Add-Ons. Jene bieten erweiterte Blickwinkel und weitere Datentiefe zur Optimierung Ihrer Produktion und aller damit verbundenen Elemente und Einheiten, wie z. B. auch Ihre Produktions- und Personaleinsatzplanung.

FLUX bietet Transparenz für jede Instanz Ihrer Fertigung

Geschäftsführung

FLUX deckt ungenutztes Potential auf, reduziert Durchlaufzeiten sowie Fehlerquoten und steigert dadurch Ihre Qualität zu optimalen Kosten.

Produktionsleiter

FLUX ermöglicht eine kontinuierliche Übersicht über die laufende Produktion und die Nachhaltige kennzahlenbasierte Optimierung jener.

IT-Leiter

FLUX kann lokal bei Ihnen oder sicher in der Cloud betrieben werden. In Punkto Datensicherheit erfüllt und übertrifft FLUX alle Standards.

Werker

FLUX bietet eine Intuitive Bedienoberfläche für Werker und eine ausgeklügelte Werkerführung mit dem Ziel der 0-Fehler-Produktion.

Auszug aus unseren Kundenprojekten

Sie möchten Ihre Produktion optimieren und wünschen mehr Transparenz?

Dann sollten Sie FLUX kennenlernen.

Wir freuen uns auf Ihre spannende Anfrage.